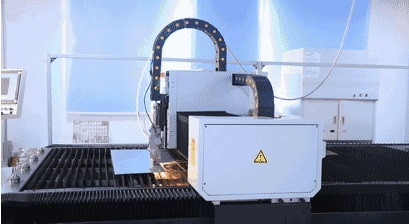

In the market of laser processing equipment, laser cutting is one of the most important application of laser cutting machine, cutting machine, punch substitution effect has become more and more obvious, the market is more popular following the 50mw laser pointer marking applications, is expected to cut high-end high power laser speed, high precision, and large format cutting thick plate for the characteristics of the cutting machine equipment market has a larger growth space.

In laser machining, laser light emitted from the laser collimation and focusing lens by the sink of the cutting head to a point (focus), operators need to ensure that the laser beam machining in the nozzle is the center, and adjust the distance from nozzle plate surface (as the plate thickness and spray nozzle), high pressure gas, and with the completion of the green laser pointer beam cutting operation. The main influencing factors are as follows:

Focus diameter: small diameter, narrow incision, cutting large diameter and small thickness; incision width, cutting thickness; focus position: determines the shape of the workpiece surface and the spot size of incision; the best position depends on the material type and thickness; power: influence of cutting plate thickness; affect the processing efficiency and deformation; cutting speed: the need to match the power, gas flow rate is too small, can lead to the formation of cut unserchable or burr; nozzle diameter: small diameter, suitable for cutting sheet; large diameter, suitable for cutting; gas: gas purity effect of burr formation and cutting surface oxidation, gas flow rate, the thinner plate, pressure to the more; beam mode: single mode effect in thin plate cutting, multimode optical larger, energy distribution, suitable for thick plate cutting.

In the face of machined shape processing materials, wide range of flexible, blue laser pointer cutting equipment can perform complex processing requirements, with high speed, high precision and high quality to meet the application requirements of automobile, aerospace, medical and health care, plastics, electrical and electronic, textile and other industries. The judgement of its cutting effect can be mainly measured from the following aspects:

Roughness: the cutting edge has more or less the lines left by cutting, and the depth of the line determines the roughness of the cutting surface. The shallower the texture, the lower the roughness and the smoother the surface. Generally speaking, the thinner the material thickness is, the lower the roughness of the cutting surface is; the lower the surface roughness is when cutting with nitrogen or argon than the oxygen. Verticality: because the cutting beam is focused by the beam divergence and the characteristics, which resulted in cutting (especially plate cutting), the spot size at different depth thickness of material is not the same, which can not be cut surface and the plate surface of the vast reach 90 degrees, or on the surface is wide or under the surface is wide. Generally speaking, the thinner the material, the better the verticality; the better the beam quality, the better the verticality. In addition, it is also related to the relative position of the machining time spot and the material thickness direction.

Burr: excellent cutting, cutting edges shall be free of burrs, and subsequent treatment shall be required due to burrs. This is related to the specific process parameters, material type and beam quality. Deformation: as the laser pointer cutting is essentially thermal cutting, the plate inevitably exists deformation, and the excellent cutting should minimize the adverse effects as much as possible. Particular attention should be paid to the cutting of thin plates. In general, the cutting speed is faster, more narrow, cutting gas flow increases, the deformation of the smaller.

http://petstopsites.com/pet-resources/misc/iphone8-will-use-rear-laser-system.html