Market research firm BBC Research released a report shows that by 2020, the global industrial lasers market size will reach 6.3 billion US dollars, of which the field of consumer electronics will become the largest industrial applications of industrial lasers, its market share is expected to reach 2 billion US dollars The With the continuous progress of science and technology, the world’s innovative consumer electronics products with each passing day, they not only look dazzling, and built a variety of complex sophisticated integrated technology. Thus, the rapid development of the electronics industry to the burning lasers for sale manufacturing industry has brought great opportunities and challenges.

Basically, laser technology uses non-contact processing, does not produce mechanical stress, especially in line with the electronics industry processing requirements. In addition, with its high efficiency, high precision, small heat affected area, no pollution and other advantages, laser processing technology is widely used in the electronics industry.

In the consumer electronics industry, laser cutting can be fine cutting or micro-machining of small parts such as metal or non-metallic parts with excellent cutting accuracy and speed. Laser welding is a small deformation of the heat, the role of the region and the location of precise control, high welding quality, easy to achieve automation, to achieve the advantages of dissimilar materials such as welding out. The 300mw green laser marking with its environmental protection, wear resistance, high precision, low cost, stable performance, the use of a wide range, easy to track and control and other characteristics applicable to a variety of thin metal / non-metallic materials marking, and in the category A wide range of electronic components branded a permanent “mark”.

Mobile Internet era has long been subversive people’s life, work and thinking mode. With the rapid development of the consumer electronics industry, smart phones has become one of the elements of life can not be missing. According to Gartner’s analysis, shipments of smartphones worldwide totaled about 1.45 billion units in 2016, up 0.6 percent year on year, and in 2017, shipments are expected to be around 1.5 billion.

Mobile phone is undoubtedly the darling of consumer electronics products. With the increasingly fierce competition in the mobile phone market, mobile phone manufacturing industry naturally put forward higher requirements. It is reported that about 70% of the mobile phone manufacturing processes are applied to 100mw laser pointer technology (more than 20 different processes) and related manufacturing equipment. Whether you can see the naked eye, or can not see, the laser figure are in different forms of “interspersed” which.

Especially with the recent high-power, deep ultraviolet and ultra-fast laser processing technology development, continued to promote the smart phone manufacturing technology leap. The reason, presumably with the laser process characteristics and precision manufacturing needs of mobile phones are closely related. With its high power density, good direction, clean, efficient, environmental protection and many other advantages, laser processing in mobile phone manufacturing to replace the traditional technology trends are increasingly evident.

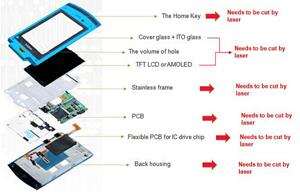

For example, precision laser cutting in the processing of many elements of smart phones, such as Home button, sapphire screen, tft LCD screen, AMOLED screen, glass cover, conductive glass, volume hole, stainless steel shell, PCB circuit board, flexible circuit board, Cover shells, and other thin film materials and brittle materials are all very useful technology. In addition, the integration of electronic components increasingly demanding, the design tends to miniaturization, many fine deep hole, such as the use of traditional processing methods will be difficult to complete, strongest laser pointer drilling has become an important means of technology. Laser focus spots can concentrate very high energy in very small areas, especially for small holes in the machining, with a minimum pore size of only a few microns and a hole depth and aperture ratio greater than 50 microns. At the same time, a mobile phone can be seen everywhere laser marking the shadow, such as: Logo, cell phone keys, cell phone shell, battery, PCB, mobile phone accessories and mobile phone parts and so on.

Asia is the world’s consumer goods industry, “production hot spots”, with its consumer electronics industry to occupy a leading position. It is expected that by 2019, the size of smartphone users in Asia will reach 2.66 billion, and this market is showing “explosive” growth, and bring a lot of laser application potential. In addition to the application of traditional laser cutting, laser welding and laser marking technology, more new laser technology is to show their talents. For example: Glass cutting process based on ultrashort pulse lasers. This type of laser is mainly used to cut the use of hardened glass and sapphire glass and other materials made of TV screen, computer screen, tablet computer and display. Another example is a low power diode 200mw green laser for welding a mobile phone camera module.

Precision machining needs are driving ultrafoot lasers represented by femtosecond and picosecond lasers in the industrial market to become more and more widely used. It is reported that by 2020, ultra-fast pulse laser market size is expected to more than 1.5 billion US dollars. Megawatt peak power, picosecond and femtosecond pulse width of the ultra-fast lasers in the 3C industry (including computers, communications and consumer electronics products such as smart phones, tablet PC devices) and other processing areas will be rapid development.

For example, mobile phones, microprocessors, monitors, memory chips and other sophisticated and sophisticated consumer electronics products and components are composed of a large number of different shaped, micro-materials, especially the need for high-precision processing technology support. In this case, ultra-fast 30mw laser pointer technology will be in its fine processing, beam control and beam transmission technology and other aspects of the advantages of favor. This technology has also become the key to the future success of manufacturing more complex consumer electronics devices.

As a result, ultrafast lasers provide unprecedented levels of extreme manufacturing and precision manufacturing, designed to overcome the bottlenecks of high, fine, sharp, hard and difficult processing of conventional processes. According to industry sources, the next three to five years, the consumer electronics market will be higher demand for smart devices, the current more popular, such as VR, AR and other new technologies will promote the further development of ultra-fast laser market.

http://laserman123.royalfa.com/post/2